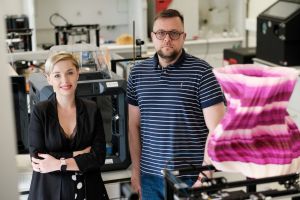

Prof Robert Przekop's team from the Centre for Advanced Technologies at AMU has created an invention allowing chemical substances to be introduced into objects printed on 3D printers. The solution may find use both in science and the economy. The joint-stock company Sygnis has purchased the licence for its use.

The tool developed by the AMU researchers is simple but, as it turned out, not noticeable - it involves the direct placement of a container of liquid in the path of a wire, which is melted and printed.

One possible use of the invention is the personalisation of pharmaceutical production. Medicinal substances can be printed directly on a 3D printer in a soluble polymer carrier. The researchers have already performed the first successful tests with an antibiotic.

- "So far, to carry out extrusion tests of pharmaceutical substances in polymers, you had to have an entire pharmaceutical-standard line consisting of big tools adequately prepared and cleaned. Now we can print objects directly on the printer from a significantly small amount of the active substance," explains the scientist.

The innovation is also suitable for agricultural use to personalise the dosage of pesticides and fertilisers. Such substances can be placed in the soil, in a polymer matrix printed on a 3D printer, from which they will be gradually released. A further implementation is the creation of three-dimensional objects with an isotopic source. - 'Our concept can be used in a wide range of disciplines,' the researcher believes.

According to Ms. Alicja Ostrowska-Leszczynska, director of the Adam Mickiewicz University Centre for Innovation and Technology Transfer, the tool opens up possibilities for simple testing of a wide range of chemical compounds added to polymeric materials. - It allows rapid screening, which does not require costly apparatus and adaptation of laboratory facilities, to test various polymer-modifier systems for their compatibility and new application uses without the need for complex modifications, redesign or reconstruction of the print head.

Source: Życie Uniwersyteckie

Photo credit: Adrian Wykrota